What is Cold Crushing Strength – CCS of Refractory Bricks ?

The cold crushing strength (CCS) of refractory bricks is a measure of their ability to withstand loads at room temperature without undergoing significant deformation or failure. It is an important property because it indicates the bricks’ ability to withstand mechanical stress and pressure during installation and service in high-temperature environments such as furnaces, kilns, and industrial processes.

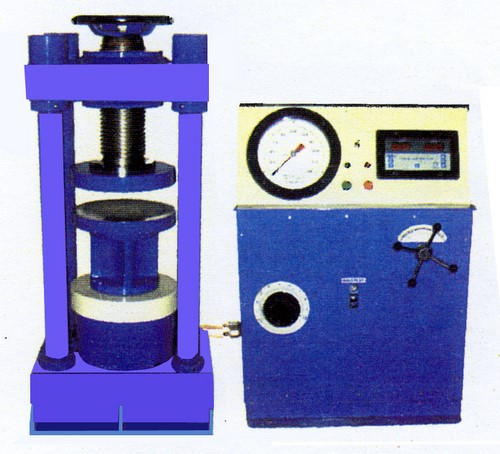

The CCS is typically measured in units of Pascals (Pa) or pounds per square inch (psi) and is determined through a standardized testing procedure. Here’s how the test is usually conducted:

- Sample Preparation: A refractory brick sample is chosen and prepared for testing. The sample is typically a cylindrical or rectangular specimen.

- Loading: The prepared sample is placed between two platens of a testing machine. A compressive load is then applied to the sample at a constant rate until it fails or fractures.

- Failure Point: The CCS is determined when the sample fractures or breaks under the applied load. The load at which this failure occurs is recorded.

- Calculation: The CCS is calculated by dividing the maximum load applied to the sample (in Newtons or pounds) by the cross-sectional area of the sample (in square meters or square inches). The result is typically expressed in Pascals (Pa) or pounds per square inch (psi).

The CCS value provides an indication of the strength and durability of a refractory brick under cold or ambient conditions. It is important to note that refractory materials may have different CCS values depending on their composition, manufacturing process, and intended application. High CCS values are desirable for applications where the bricks will be subjected to high mechanical stresses, such as in the linings of industrial furnaces and kilns.

In India, the Cold Crushing Strength (CCS) of refractory bricks is often measured and reported in kilograms per square centimeter (kg/cm²) as the unit of measurement. This unit is commonly used in the Indian refractory industry. However, it’s essential to be aware that different regions and organizations may use various units, so it’s always important to check the specific units mentioned in the documentation or standards of the materials being tested.