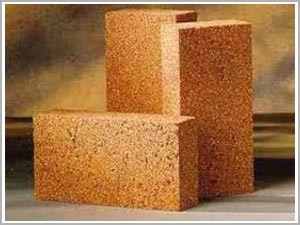

Fire bricks are special kind of bricks that possess the capacity to withstand high temperatures. They’re high heat resistant and can be in different shapes. The main usage of fire bricks are for lining of the furnaces, bake ovens, and pits. These bricks contains mainly aluminum oxide and silicon dioxide. Since they are manufactured in very high temperatures, they have the capacity to withstand high temperatures.

Different Variety of Fire Bricks Available

The different types of bricks are used for different purposes. These products were usually made of clay and were used for different purposes. Following is the variety:

- Medium Duty

- High duty

- Insulation bricks

- Clay bricks

They’ve got innumerable uses. They’re considered to be the most versatile and indispensable product because they are used in wide variety of fields. The pizza ovens are also made out of refractory bricks.

Our products are highly appreciated in the market because of our maintenance, our cleaning and constant replacement services. In order to avoid constant replacements or damage, the soot from the bricks needs to be removed very often. Also, our guidance brochure instructs proper use of detergents to clean the plates of the oven thoroughly. Our years of experience in the field have made us known for being premium refractory fire brick manufacturers and exporters India.

In order to maintain the durability, these bricks need to be cleaned properly. The main part is using the right bricks so that it’ll seldom require repairs and maintenance. We manufacture industrial fire bricks using highly advanced machineries and techniques. These machines are highly efficient to bare and fit different sizes of bricks.

Technical Specifications

| Particulars | RC IS6 | RC SPECIAL | RC 40 | RC 45 | RC 40S | RC 45S | RC 42D | RC 50 | RC 55 | RC 60 | RC 70 |

| Al2O3(Min) | 30 | 34 | 40 | 45 | 40 | 45 | 42 | 50 | 55 | 60 | 70 |

| Fe2O3(Max) | 2.5 | 2.5 | 2.8 | 3.0 | 2.0 | 2.0 | 1.5 | 3.0 | 3.5 | 3.5 | 3.5 |

| PCE(Min) | 29 | 30 | 32 | 32 | 33 | 33 | 34 | 33 | 33 | 35 | 36 |

| Apparent Porosity (%) Max |

26 | 25 | 24 | 24 | 22 | 21 | 18 | 24 | 24 | 24 | 23 |

| CCS (kg/cm²) | 200 | 250 | 300 | 350 | 300 | 350 | 500 | 400 | 400 | 450 | 550 |

| RUL °C (Max) | 1300 | 1350 | 1400 | 1400 | 1420 | 1440 | 1470 | 1400 | 1410 | 1450 | 1460 |

|

Bulk

Density(gm/cc)

|

2.0 | 2.05 | 2.15 | 2.20 | 2.20 | 2.25 | 2.30 | 2.30 | 2.45 | 2.50 | 2.65 |

| PLC (%) Max | ±1.0 at 1300 °C/2 hrs |

±1.0 at 1350 ° C/2 hrs |

±1.0 at 1400 ° C/2 hrs |

±1.0 at 1400 °C/2 hrs |

±0.75 at 1450 ° C/2 hrs |

±0.8 at 1450 ° C/2 hrs |

±0.5 at 1450 ° C/2 hrs |

±1.0 at 1450 ° C/2 hrs |

±1.5 at 1450 ° C/2 hrs |

±2.0 at 1450 °C/2 hrs |

±2.5 at 1500 °C/2 hrs |

| Application Area |

For Chimney flue, Boiler & Sugar Industry |

For Chimney flue, Boiler,Cu pola & Steel foundry |

For Cement preheater , cyclone, silicate furnace & other moderate heat duty applicatio ns |

For Cement preheater, cyclone, silicate furnace & other moderate heat duty applicatio ns |

Special purpose Low iron high duty bricks for Cement Preheater & Cyclone |

Special purpose Low iron high duty bricks for Cement Preheate r & Cyclone, Chemical plant & Blast furnace |

Special purpose Low iron high duty bricks for Cement Preheate r & Cyclone, Chemical plant & Sulphur furnace |

Low porosity dense bricks for Abode backing furnace & Blast furnace |

For cement kiln preheatin g zone & Reheatin g furnace wall. |

Calcinatio n zone of Cement rotary kiln & Copper melting furnace |

Reheating furnace wall, Burning zone of cement rotary kiln & Ladle backup |