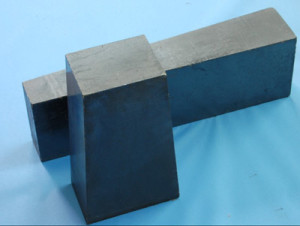

Ravani Ceramics is one of the leading manufacturer of Magnesia Carbon Bricks in India. Magnesia Carbon Bricks are the non-fired basic refractory. It enhances the corrosion resistance and slag resistance.

Types of Magnesia Carbon Bricks :

- Magnesia Carbon Bricks

Magnesia Carbon Brick is a resin-bonded brick produced from dead-burned or fused magnesia and graphite. Anti-oxidant is also added if needed. Magnesia-Carbon brick works well in thermal resistance, corrosion, resistance, and spalling resistance.

Where it is used ?

Magnesia Carbon Brick is used in converters, EAFs ( Electric Arc Furnaces ), ladles and refining furnaces.

- Magnesia-Alumina Carbon Brick or Alumina-Magnesia Carbon Brick

Magnesia-Alumina Carbon Brick or Alumina-Magnesia Carbon Brick is produced from high quality bauxite, corundum, fused magnesia and graphite. Alumina-Magnesia Carbon brick has proper residual expansion, low thermal conductivity, and better insulation performance than that of Magnesia-Alumina Carbon brick which contain much more magnesia.

Where it is used ?

It is used in the slag line of the ladle, lower part of the ladle wall, ladle bottom and free zone of the ladle.

- Magnesia-Calcium Carbon Brick

Magnesia-Calcium Carbon Brick is produced from good quality magnesia, dolomite clinker and synthetic magnesia dolomite clinker. It is a good resistant of slag and has a good stability in high-temperature vacuum working environment and can also purify the liquid steel

Where it is used ?

It is used mainly in refining furnaces such as UOD, AOD and LF ( Ladle Furnace ).